News Detail

YangSen offers remarkable products, fast services, and punctual delivery time.

12

2024

-

11

The Difference Between Accuracy and Repeatability in Machining

Author:

This article explains the differences between accuracy and repeatability, their importance in CNC machining, and how each affects the manufacturing process.

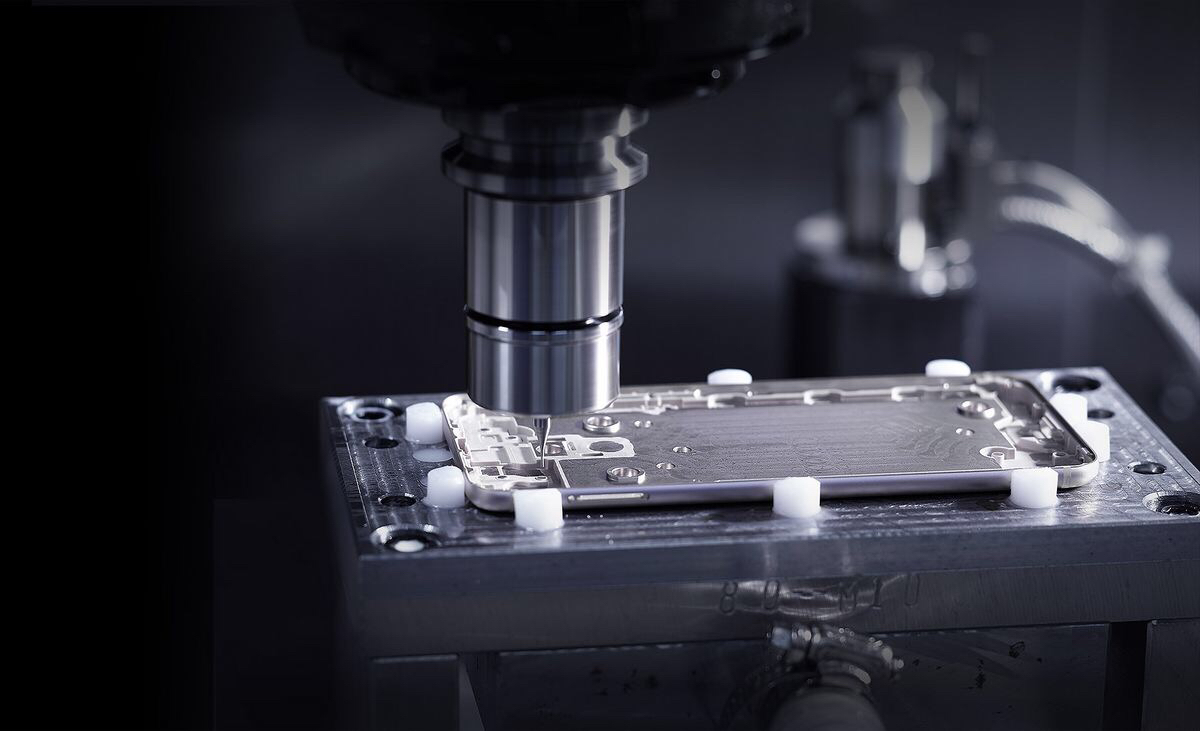

In machining and manufacturing, two essential terms—accuracy and repeatability—define the quality and performance of a machine. While both accuracy and repeatability are critical for producing precise parts, they measure different aspects of machine performance. This article explains the differences between accuracy and repeatability, their importance in CNC machining, and how each affects the manufacturing process.

What is Accuracy?

Accuracy refers to how closely a machine can produce parts that match the intended or target specifications. In other words, accuracy is the degree of closeness between the measured value and the true or desired value. For a CNC machine, accuracy indicates its ability to position tools or move along programmed coordinates with precision, aligning closely with the design specifications.

Example of Accuracy in CNC Machining: If a CNC machine is programmed to drill a hole exactly 10 millimeters in diameter, accuracy measures how close the actual hole diameter is to 10 millimeters. If the drilled hole diameter is 10.01 mm or 9.98 mm, this deviation shows how accurate (or inaccurate) the machine is relative to the target.

Importance of Accuracy: High accuracy is crucial for achieving parts that meet design specifications, especially in industries such as aerospace, medical, and automotive, where tight tolerances are essential. High accuracy ensures that parts fit together correctly, operate safely, and perform as expected.

What is Repeatability?

Repeatability refers to a machine's ability to produce the same result consistently across multiple operations or parts. A highly repeatable machine can perform the same task with minimal variation each time, even if there is a slight offset from the intended specification. Repeatability measures consistency rather than closeness to a target value.

Example of Repeatability in CNC Machining: If a CNC machine drills a series of holes with a target diameter of 10 millimeters and consistently produces holes that measure 10.02 mm, then the machine is repeatable, as the results are consistent. However, it may lack accuracy because the actual hole size does not match the intended target.

Importance of Repeatability: Repeatability is essential for maintaining quality control, especially in high-volume production environments. Inconsistent results may lead to higher rates of rejects, increased rework, and overall inefficiency. With good repeatability, manufacturers can ensure that each part is virtually identical, which is vital for assembly and product reliability.

Key Differences Between Accuracy and Repeatability

| Criteria | Accuracy | Repeatability |

|---|---|---|

| Definition | Closeness to the true or intended target value | Consistency in producing the same result repeatedly |

| Focus | How close the machine gets to the target | How consistent the machine's output is over time |

| Measurement | Deviation from the target (measured in units) | Deviation in repeated measurements (measured in units) |

| Example | A hole diameter matches the exact target value | Hole diameters are slightly off-target but consistent in size |

| Effect on Quality | Ensures parts meet design specifications | Ensures uniformity in part production |

The Relationship Between Accuracy and Repeatability

While accuracy and repeatability are distinct, they are often interconnected. A CNC machine that is both accurate and repeatable can produce parts that closely match the intended design specifications every time. However, achieving both can be challenging and may require high-quality components, precise calibration, and regular maintenance.

In some cases, a machine may be highly repeatable but not accurate, or vice versa:

- High Repeatability, Low Accuracy: The machine consistently produces parts that are slightly off from the target but with minimal variation.

- High Accuracy, Low Repeatability: The machine can hit the target specifications but struggles to do so consistently.

In practice, most manufacturing applications require a balance of both accuracy and repeatability, as both contribute to the overall quality and functionality of the final product.

Achieving High Accuracy and Repeatability in CNC Machining

To optimize accuracy and repeatability, consider these key factors:

1. Machine Calibration and Maintenance

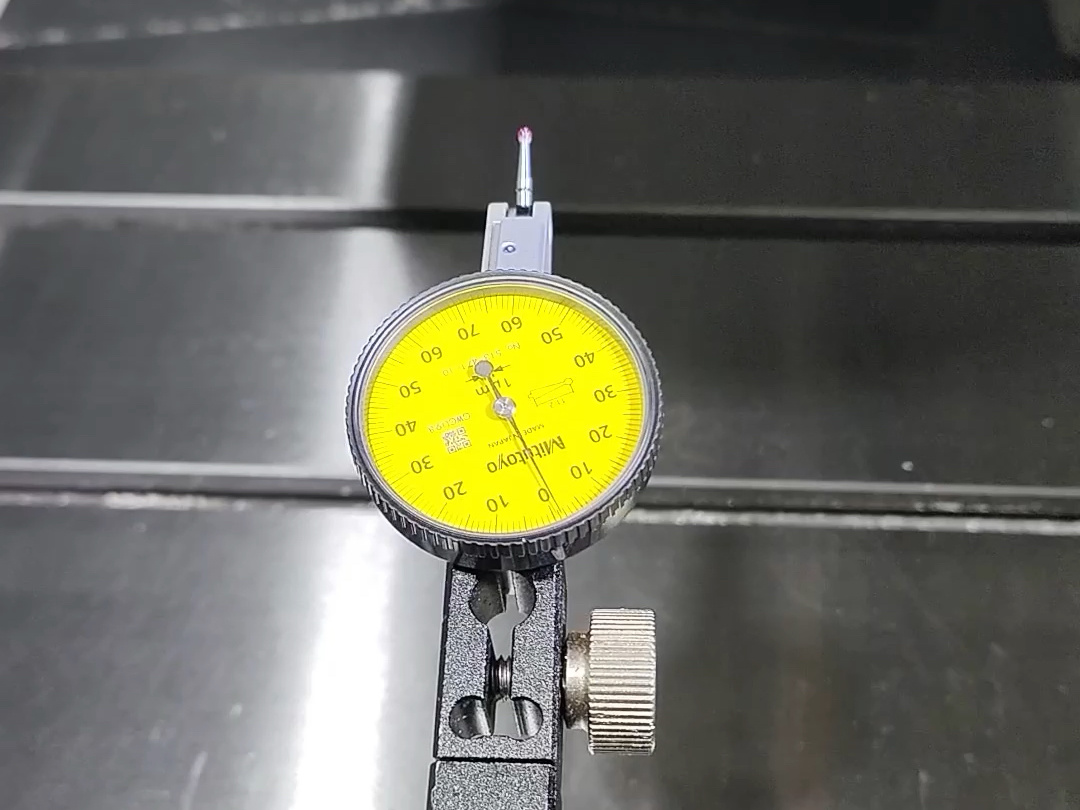

Regular calibration and maintenance are essential for sustaining accuracy and repeatability. Wear and tear on machine components can cause deviation from target values and reduce consistency over time. Periodic checks help ensure the machine stays aligned with specifications.

2. Quality of Machine Components

High-quality machine components, such as ball screws, linear guides, and spindles, improve precision and consistency. Precision components are engineered to minimize backlash and vibration, both of which affect accuracy and repeatability.

3. Environmental Control

Temperature fluctuations, humidity, and vibration from nearby equipment can impact a machine’s performance. Keeping the machining environment stable minimizes expansion or contraction of machine parts, which helps maintain both accuracy and repeatability.

4. Operator Skill and Training

A skilled operator can optimize CNC parameters, set up parts correctly, and monitor processes to ensure consistency. Well-trained operators understand the nuances of each machine, allowing them to adjust for minor issues before they impact production.

5. Advanced Control Systems and Feedback

Modern CNC machines equipped with feedback systems, such as encoders and sensors, can detect deviations in real-time and make necessary adjustments. Closed-loop control systems can improve both accuracy and repeatability by providing constant feedback to correct any variations during operation.

Accuracy vs. Repeatability: Which is More Important?

The importance of accuracy versus repeatability depends on the specific application:

- Accuracy is more critical in applications where parts need to meet precise specifications, such as in medical devices, aerospace components, or precision engineering.

- Repeatability is crucial in high-volume production, where the ability to produce consistent parts ensures product uniformity, reducing waste and the need for rework.

In many cases, however, both accuracy and repeatability are equally important, as they contribute to overall quality control and manufacturing efficiency. A well-calibrated CNC machine should ideally provide both high accuracy and high repeatability to meet the demands of modern manufacturing.

Conclusion

Understanding the difference between accuracy and repeatability is essential for evaluating and optimizing CNC machine performance. While accuracy ensures that parts meet exact design specifications, repeatability ensures that each part is produced consistently. By maintaining both, manufacturers can achieve high-quality production, improve efficiency, and reduce waste.

Investing in high-quality equipment, regular maintenance, and skilled operators can help achieve both accuracy and repeatability, ultimately leading to better product quality and customer satisfaction.