R&D Capability

It is our life and top priority to meet the various needs of customers continuously. Inspired by this in mind, we organized and equipped a strong R&D department and technical department that possesses a unique and innovative spirit, since 2003.

1.operative technology

More than 7.5% of our annual turnover is allocated yearly as funding for research and development, in order to promote independent R&D capabilities and make continual improvements to the precision and affordability of various CNC machine tools.

1.The Ansys finite element analysis system locks the stress division of each component of the fuselage, analyzes the vibration source, and analyzes mechanical and physical change factors such as temperature rise change and structural displacement.

2.High-rigidity structure design, one-piece high-rigidity doorpost, symmetrical structure design, effectively reduce thermal deformation and ensure long-term machining accuracy of machinery. FEM structural simulation, stress-strain analysis, provides the best dynamic cutting rigidity. The minimum overhang design of the head, the best cutting quality, the full stroke of the base supports the table, and obtains the best dynamic balance.

2.Independent research and development of S800 CNC system:

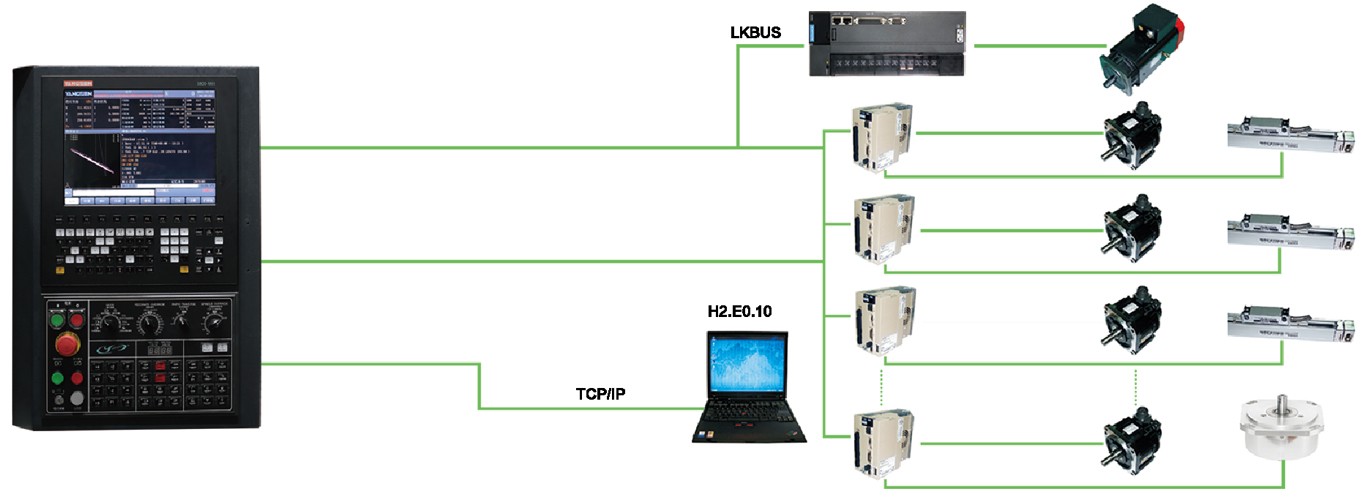

System Introduction:

The company's self-developed YS-S800 system uses a 32-bit micro-processing embedded chip as the core of the system's main control module. t has powerful functions, rich built-in resources, and a 15-inch TFT color LCD screen man-machine interface display.

Main technical advantages:

· The CPU has fast processing speed and supports floating-point operation, which greatly improves the speed and accuracy of motion interpolation calculation;

· The system supports ten-axis control and 4-axis linkage interpolation function. It can perform various two-dimensional and three-dimensional complex processing;

· The communication interface of the system is universal. it adopts 100M network interface technology for the transmission of NC codes, and through the network interface technology, the unified management and on-line diagnosis of the production workshop can be easily realized, and the MECHATROLIN high-speed servo synchronous bus control technology can be supported, which is in line with the world-class bus NC control technology.

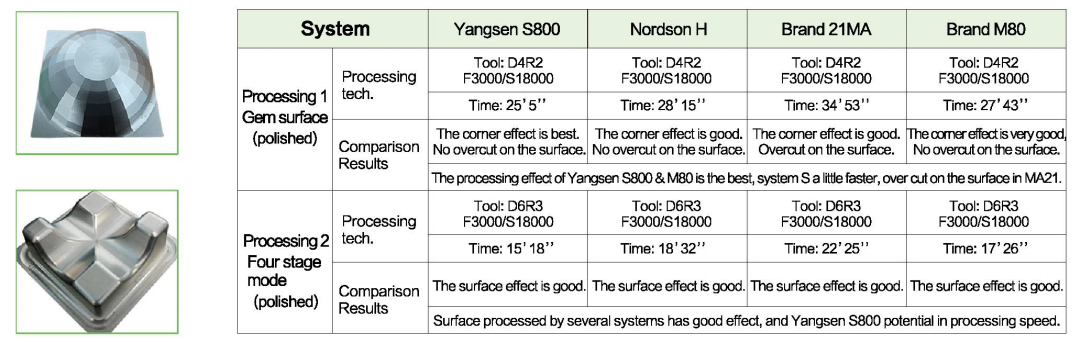

System Processing Comparison Table:

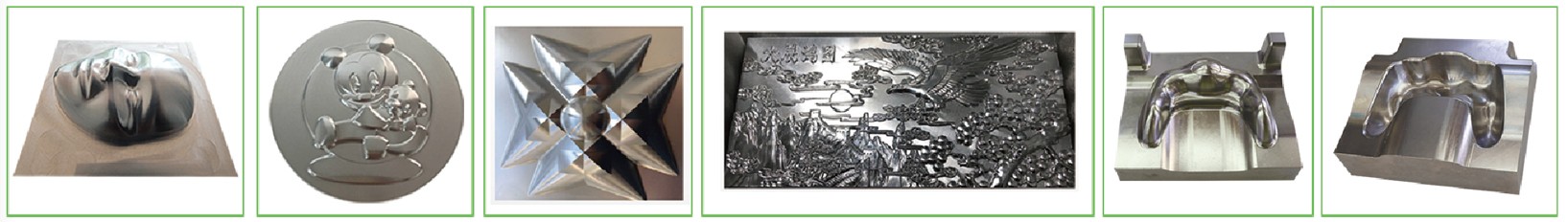

Engraving Machine Samples:

3.More than 50 utilize-type Patens.

Our commitment to innovation and excellence is demonstrated by our numerous Utility Model patents. These patents are a testament to our strong R&D capabilities, allowing us to continually develop cutting-edge technologies and advanced CNC solutions that meet the evolving needs of our clients. Our ability to secure these patents highlights our dedication to pushing the boundaries of CNC machining, ensuring that our products remain at the forefront of industry standards.

CERTIFICATE

CERTIFICATE

CERTIFICATE

CERTIFICATE

CERTIFICATE

CERTIFICATE

CERTIFICATE

CERTIFICATE

CERTIFICATE

CERTIFICATE