Why Choose Yangsen

Strive for Perfection, Create High-Quality Products

Yangsen takes science and technology as the driving force. Focused unremittingly grasps product quality,creates a high-quality brand and casts a first-class corporate image. Adapting the production system tothe ever-changing production requirements and to better satisfy our customers, the factory has alwaysadvocated lean production and created high-quality brands.

1.Outstanding CNC Machine Brand

No.1 CNC Machine manufacturer in Fujian and Top 20 CNC Machine manufacturer in China. Over 1 billion RMB Annual output. Top 100 specialized and sophisticated enterprises in Fujian Province.

We have:

· More than 17 years’ experience

· Over 57,000 square meters factory and over 500 employees

· Over 4000 sets annual production capacity

· Strict quality control system

· Professional production manage system ISO9001

· On-time delivery

· Excellent quality and reasonable price

· Strict confidentiality for clients

· Complete after-sales service

· Exporting to 20+ countries

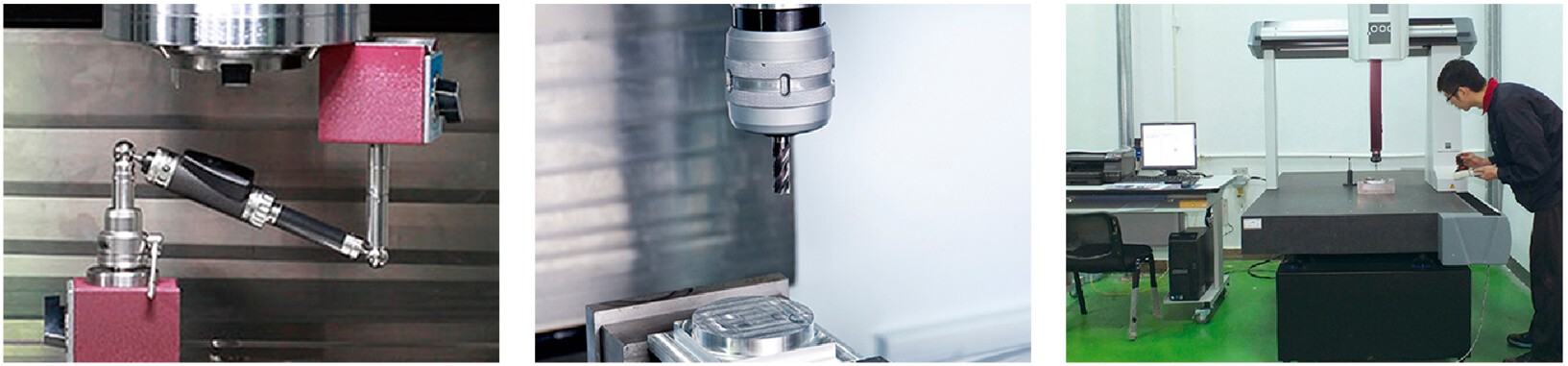

2.Strict quality control system

Our quality inspection department is composed of a group of careful and patient young people who have been working in the machine tool industry for more than 5 years.

Each machine tool can only leave the factory after our QC team pass the inspection. In special cases, acceptance inspection can also be carried out at the location designated by clients. The acceptance inspection of machine tools is divided into type inspection and our own internal inspection of normal production products.

1.Type inspection

Type inspection is to comprehensively evaluate the technical level of machine tool structure design, and to check whether the design and manufacture of machine tools can meet the requirements of clients and whether they meet the requirements of relevant standards and technical documents. Propose topics that need in-depth study and measures to improve the design. Type inspection should be carried out in any of the following situations: when new products are trial-manufactured or identified for finalization; or when the structure and performance of the machine tool have undergone major changes.

Type Inspection items are as follows:

1. Noise test, GB/T16769-1997

2. Absolute and relative vibration test, ISO2372

3. Thermal deformation test, GB/T 18400.10-2021

4. Static stiffness test GB/T 13574-1992

5. Transmission efficiency test,

6. Vibration resistance cutting test

7. Vibration test

8. Position accuracy test GB/T 17421.1-1998

9. Rotation accuracy test,

10. Uniformity test of linear motion ISO 1940-2-1997

11. Transmission accuracy test

12. The machining accuracy test, each axis is tested for verticality and parallelism, and it is required to be within 0.01mm.

13. Reliability test. GB/T 23567.1-2009.

For various types of machine tools, you can choose test items or add new items according to the machine tool's structural and functional characteristics and your own specific conditions.

2.Internal inspection

Our internal inspection of normally produced products is to assess whether the manufacture of the machine tool conforms to the provisions of relevant standards and technical documents, and to assess whether the quality of the machine tool is stable. The contents of the machine tool factory acceptance inspection are as follows:

1. Appearance quality

2. Inspection of accessories and tools

3. Parameter test

4. Dry running test of machine tool

5. Load test of machine tool

6. The precision inspection of the machine tool and the dynamic balance detection of the spindle table ensure the machining accuracy of the spindle. Spindle yaw test, 300mm requires within 0.005mm to ensure spindle accuracy and verticality. Spindle pulling test to detect the broaching force of each spindle.

7. In the work test of the machine tool, different intelligent CNC machines need to automatically load and unload different workpieces. Therefore, before leaving the factory, the function of grabbing and placing parts should be repeatedly tested. For processing inspection, each machine tool need to produce a standard test workpiece, and each workpiece must be tested by Hexagon three-coordinate instrument to ensure the machining accuracy of the machine tool.

8. For the aging test of the machine tool, the after-sale warranty of our CNC machine tools is 1 year. In order to ensure our quality, our CNC machine tools are shipped after the aging test.

9. In the circuit self-test test, within 2 seconds after the power is turned on, self-test is implemented to ensure that there is no fault. In addition, during normal operation, real-time self-test is also performed to ensure that the intelligent CNC machine tool truly plays a protective role.

10. Laser detection, full-stroke motion accuracy has been corrected and compensated by laser to ensure the positioning accuracy and reset positioning accuracy of the machine.

11. Ballbar roundness test, it is required to be within 0.012mm for 300mm range to ensure the accuracy of the machine tool.

3.Name brand mechine components

In order to ensure that we provide you with 100% reliable products, the key spare parts we choose for you are all world-renowned manufacturers that have been strictly selected and passed our strict supply chain management system.

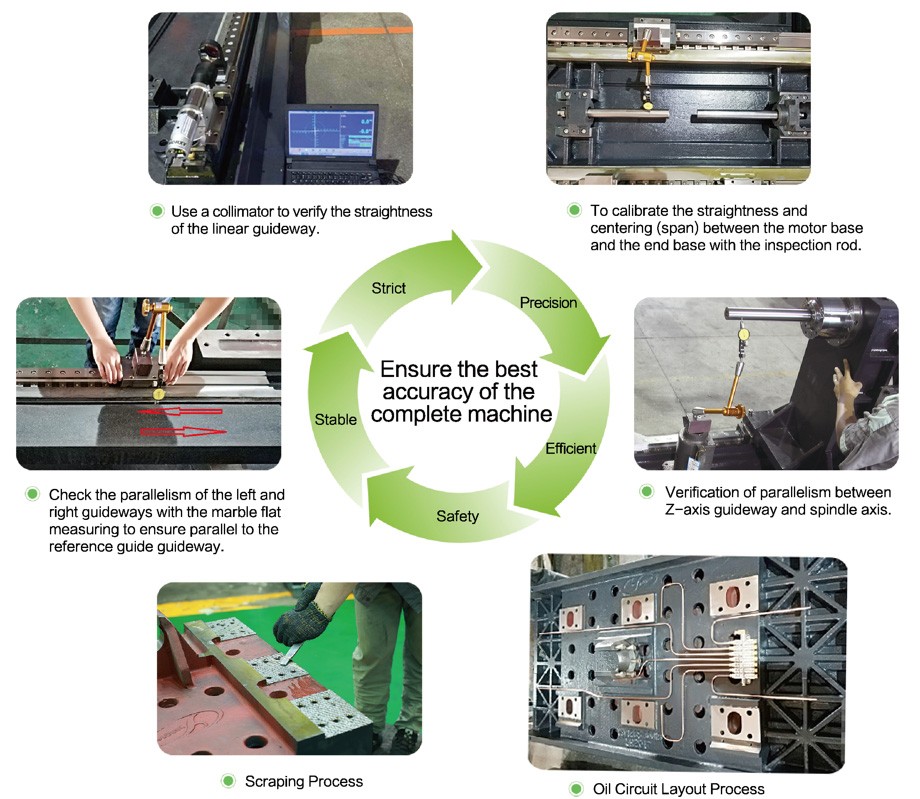

4.Production Processes

You can enjoy satisfying services provided by the production team with a total of more than 300 production line employees and 60% of them more than 10 years of experience, from Primary Machine Department, First Machine Assembling Department and Second Machine Assembling Department. Therefore, our technical processing is very stable, the production efficiency is always high, and the 100% yield rate before shipment. Such a complete production process helps you to minimize costs.